Why Two Sorters Outperform One in Real Barns

Shifting the Narrative: The Case for Dual-Sorter Design in Modern Swine Production

When it comes to pig flow, barn layout, and long-term ROI, the number of sorters you install isn’t just a design choice — it’s a production strategy.

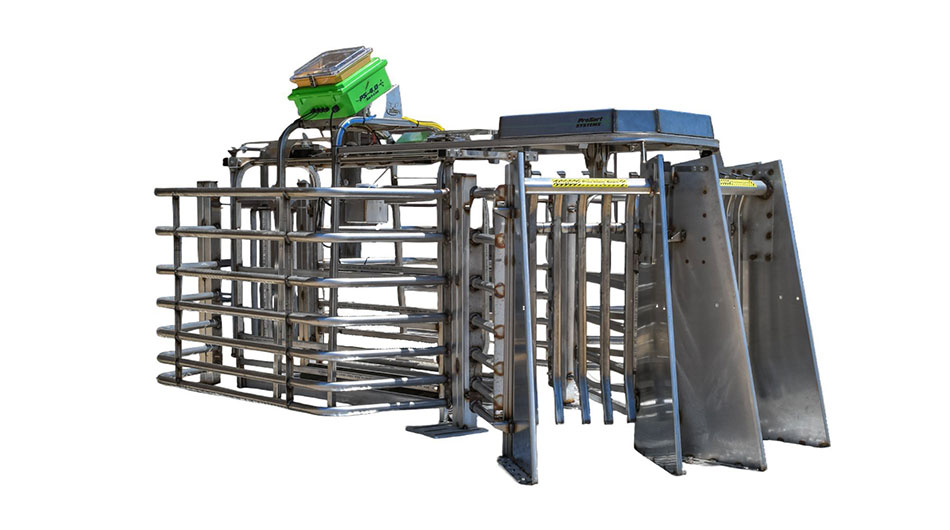

At ProSort, we’re challenging the industry norm with a simple but powerful idea: two sorters outperform one in the real-world conditions of commercial hog barns. As the industry evolves and producers demand more flexibility, flow efficiency, and easier maintenance, the dual-sorting approach isn’t just different — it’s smarter.

Some companies, like Brand X, promote a single-sorter system with a gate-flipping mechanism that alternates between two 600-head sections. While this may appear efficient on paper, in practice it introduces:

- Stress points

- Animal hesitation

- Logistical backups

In contrast, ProSort’s dual-sorter system assigns one sorter per 600-head section, creating independent, seamless flow and reducing hesitation at the gate.

Eliminates gate-flipping confusion and reduces pig hesitation — a major cause of pile-ups and stress.

If one sorter goes down, the other keeps working — offering reliability that single-sorter systems can’t match.

Designed to fit your barn — not force you to design around the equipment.

Fewer moving parts. No complex gate logic. Less downtime. Easier training.

We don’t just test equipment — we build it, install it, and use it in real barns. ProSort was designed with the producer in mind: the one managing flow, weight distribution, and logistics every single day.